Product Description

1. Introduction to E&N HONJIA Laminated Glass

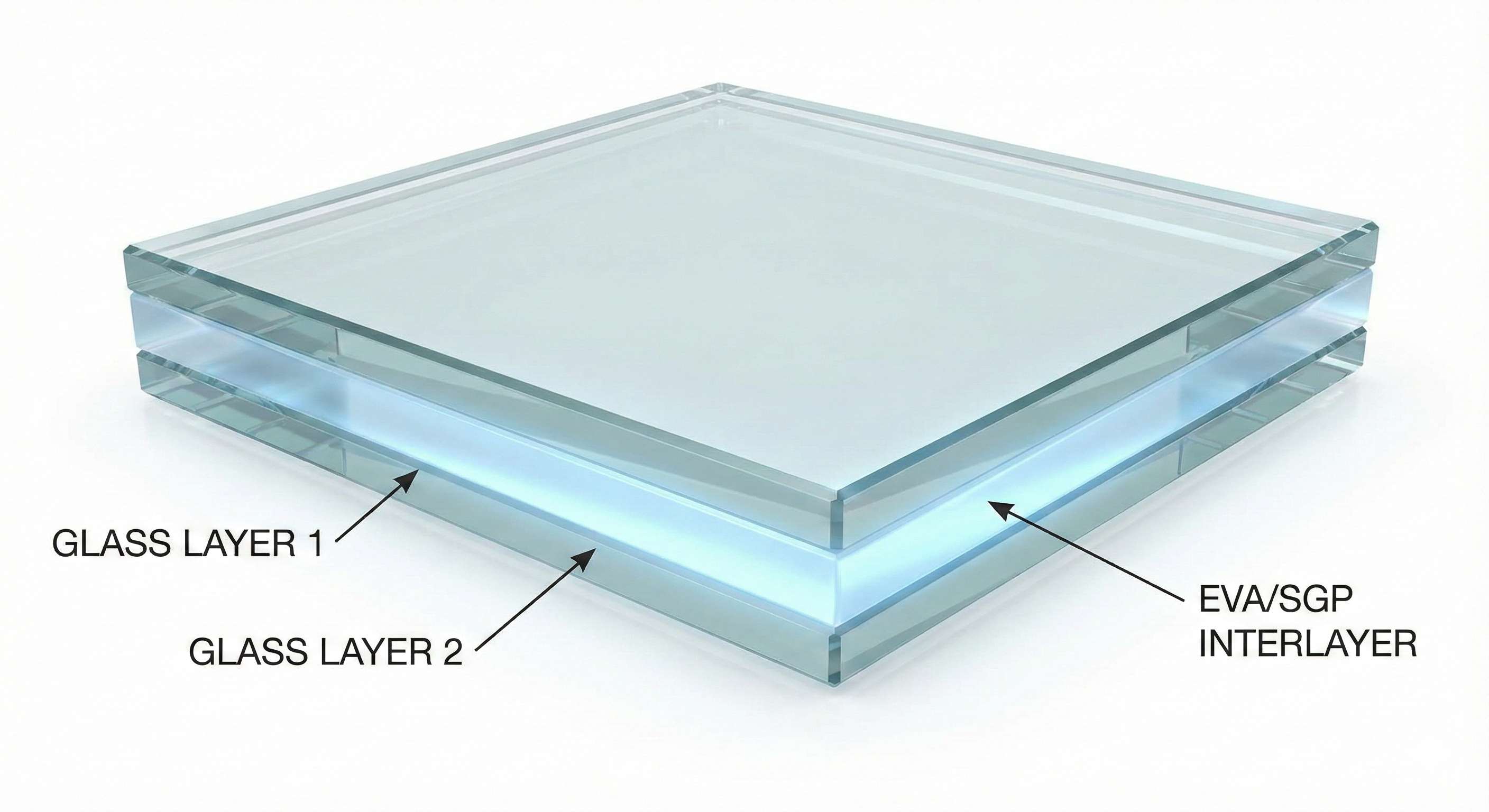

E&N HONJIA laminated glass integrates high‑quality glass with advanced interlayer technologies including EVA Film, SGP Ionoplast Film, and PDLC Smart Film. With over 15 years of R&D experience, E&N HONJIA is recognized globally for its stable formulations, premium optical performance, and long-term durability.

Our laminated glass provides excellent bonding strength, moisture resistance, edge stability, and structural performance. Whether used for façades, railings, skylights, canopies, smart partitions, or decorative glass, E&N HONJIA laminated glass meets international safety and performance standards.

2. What Makes E&N HONJIA Laminated Glass Different?

2.1 Advanced Interlayer Technology

- EVA Series: Ultra-clear, outdoor-grade, moisture-resistant, fast-curing

- SGP Series: Structural ionoplast interlayer for load-bearing systems

- PDLC Series: High-clarity smart film for privacy glass

2.2 High Transparency & Low Haze

E&N HONJIA ensures batch stability, high clarity, low haze, and excellent weather durability under humid, tropical, or coastal environments.

2.3 Superior Structural Integrity with SGP

SGP laminated glass provides:

- 5× the strength of PVB

- Up to 100× stiffness

- Exceptional creep resistance

- High edge stability

Ideal for canopies, balustrades, floors, and large spans.

2.4 Reliable Smart Glass Integration

PDLC laminated with E&N HONJIA EVA provides:

- Fast switching

- High contrast

- Clear ON-state transparency

- Stable lamination with no delamination

2.5 Global Processing Support

We provide lamination curves, technical guidelines, troubleshooting assistance, and engineering recommendations.

3. Laminated Glass Collections

3.1 EVA Laminated Glass

Benefits: high clarity, moisture resistance, anti-yellowing, strong adhesion, PDLC compatibility, decorative options.

Applications: partitions, interiors, façades, signage, smart glass.

3.2 SGP Structural Laminated Glass

Benefits: high strength, stiffness, reduced deflection, superior safety.

Applications: railings, balustrades, canopies, skylights, curtain walls, floors.

3.3 PDLC Laminated Smart Glass

Benefits: instant privacy, high clarity, uniform haze, stable bonding.

Applications: hotels, offices, luxury homes, medical facilities.

3.4 Custom Laminated Options

Colored EVA, fabric/mesh interlayers, acoustic laminated glass, multi-layer security glass, gradient or decorative designs.

4. Performance Advantages

- Safety: fragments remain bonded

- UV protection ≥ 99%

- High transparency and aesthetics

- Outdoor weather durability

- Structural stability (SGP)

- Excellent acoustic reduction

- Compatible with smart and decorative functions

5. Applications

Architecture: façades, frameless railings, skylights, floors.

Interior: partitions, PDLC privacy rooms, commercial displays.

Specialty: security buildings, public spaces, healthcare, transportation hubs.

6. Why Choose E&N HONJIA?

- True materials technology manufacturer

- Export-grade quality stability

- Full ecosystem: EVA, SGP, PDLC, accessories

- Professional technical guidance

- Trusted in 80+ countries

- Continuous innovation

FAQ

Q1: What is the difference between E&N HONJIA EVA and SGP laminated glass?

A1:EVA is ideal for interior, decorative, and smart glass applications. SGP is designed for structural and high-load installations.

Q2: How does E&N HONJIA ensure long-term outdoor durability?

A2:Our interlayers undergo UV aging, humidity aging, and thermal cycling. Outdoor EVA and SGP resist yellowing, delamination, moisture, and creep.

Q3: Can E&N HONJIA laminated glass be used for exposed-edge installations?

A3:Yes. SGP offers outstanding edge stability, stiffness, and weather resistance, making it ideal for frameless railings and canopies.

Q4: How does PDLC perform when laminated with E&N HONJIA EVA?

A4:PDLC laminated with our EVA provides strong adhesion, high clarity, uniform haze, and temperature-stable performance.

Q5: What lamination parameters does E&N HONJIA recommend?

A5:We provide full lamination curves tailored to EVA and SGP systems, including heating rate, temperature, vacuum duration, and pressure requirements.

Q6: What causes bubbles or delamination?

A6:Common reasons include insufficient vacuum, surface contamination, incorrect heating curve, or excessive humidity. We provide troubleshooting guidance.

Q7: What safety standards can E&N HONJIA laminated glass meet?

A7:Depending on construction: EN 14449, EN 12150, ASTM C1172, SGCC structural requirements, and international safety glazing standards.

Q8: How does E&N HONJIA ensure batch consistency?

A8:Automated production, strict raw material control, optical testing, traceability, and export-grade QC.

Q9: Can E&N HONJIA support large-scale project material supply?

A9:Yes. We provide engineering recommendations, stable batch supply, and technical support for global architectural projects.

Q10: Does E&N HONJIA offer custom laminated structures?

A10:Yes—color EVA, fabric, mesh, security configurations, gradient designs, embedded LED or metal components.

Q11: How are materials packaged for international shipping?

A11:Moisture-proof film, foam protection, reinforced wooden crates, palletized loading.

Q12: Does E&N HONJIA provide after-sales technical support?

A12:Yes—training, production troubleshooting, engineering consulting, material compatibility guidance, and ongoing updates.