EVA vs. SGP vs. PVB: A Comparative Analysis and Selection Guide for Structural Interlayer

In modern architecture and advanced glass processing, glass is no longer merely a "filler," but has become a load-bearing "skeleton." From the glass staircases of Apple retail stores to the suspended swimming pools of skyscrapers, structural glass is pushing the limits of engineering.

However, the fate of these laminated glass structures often depends not on the glass itself, but on the thin layer of polymer material sandwiched in between—the interlayer.

Today, we will delve into a "three-way battle" in the world of materials: EVA, SGP, and PVB. As industry professionals, how do we evaluate these three mainstream interlayer technologies for laminated glass? Especially in structural applications, which one is the true champion?

Why Structural Interlayers Determine the Safety and Performance of Laminated Glass

Structural laminated glass must not only be transparent but also "impact-resistant."

Traditionally, glass is considered a brittle material. However, in the structure of laminated glass, the interlayer plays a dual role as both a "ligament" and an "adhesive." It is responsible for permanently bonding the two pieces of glass and bearing the remaining load after the glass breaks, preventing penetration or collapse.

For structural engineers, "interlayer selection" is one of the most critical decisions in the entire curtain wall or railing design. Choosing the wrong interlayer not only means potential delamination or yellowing, but also that the glass may fail to provide the expected safety protection under extreme weather or impact.

Although PVB has dominated the market for decades, the market landscape is undergoing a dramatic shift with the advancements in clear EVA interlayer technology and the increasing popularity of SGP. Understanding the differences in their roles in structural applications is essential for every glass professional.

Interlayer Technology for Laminated Glass: An Analysis of Three Mainstream Technologies

Interlayer Technology for Laminated Glass

To understand the performance differences, we must first look at the essence. These three materials represent three distinctly different polymer chemistry approaches.

PVB (Polyvinyl Butyral): This is a thermoplastic material. Its characteristics include softness and high elongation. PVB is like a strong "gummy bear," capable of absorbing impact energy very well (which is why it's the standard for car windshields), but it is prone to creep under continuous load.

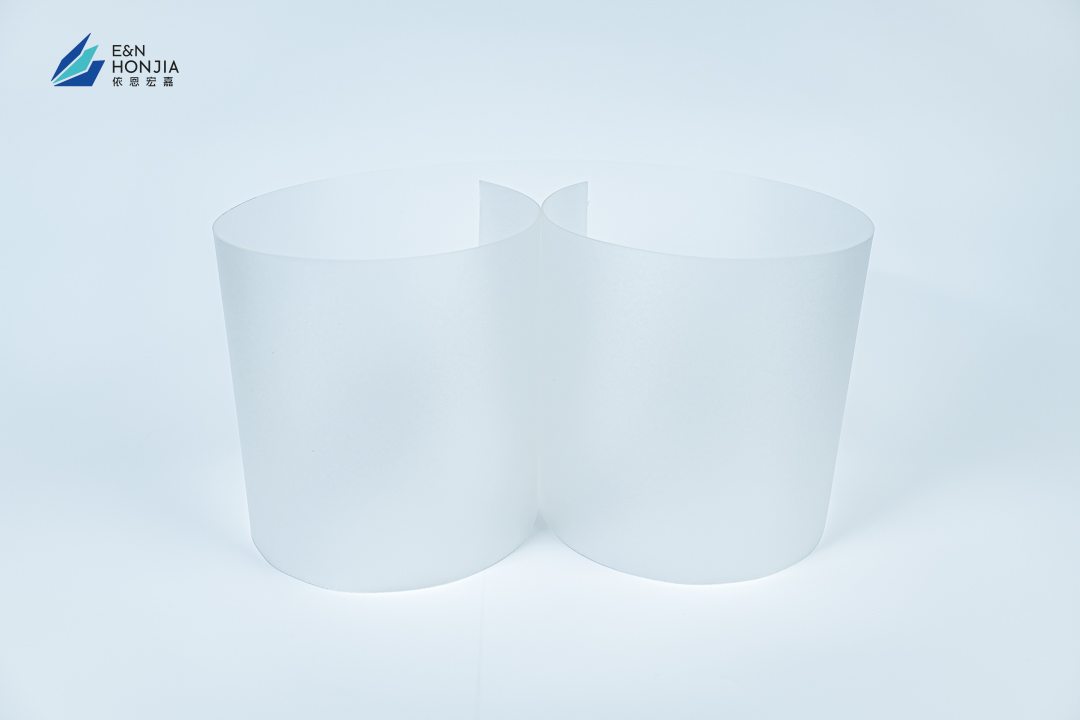

EVA (Ethylene Vinyl Acetate): Especially EVA film for glass lamination, is a thermosetting material. During the lamination process, EVA undergoes a cross-linking reaction, forming a three-dimensional network structure. This means that once cured, it will not soften and flow like PVB when heated.

SGP (Ionoplast): SGP (SentryGlas Plus) is an ionic interlayer. Its chemical structure contains metal ionic bonds, which gives it extremely high strength and rigidity. Ionoplast Interlayer is both hard and tough, a material specifically designed for structural engineering.

The fundamental differences between these three interlayer technologies for laminated glass determine their performance in subsequent mechanical property comparisons.

Clear EVA Interlayer: A Structural Option Balancing Processing Adaptability

Many people still have the old impression of EVA being used only in "photovoltaic module encapsulation." In fact, modern high-quality Clear EVA interlayers have become a dark horse in architectural glass.

1. Extremely High Transparency and Aesthetic Value

Compared to the yellowish haze that often appears in PVB, high-quality Clear EVA interlayers offer near-crystal clarity. Its haze is extremely low, making it ideal for use with ultra-clear glass, resulting in excellent visual effects.

2. Excellent Moisture Resistance and Edge Stability

This is EVA's biggest structural advantage over PVB. PVB is highly hygroscopic, leading to whitening and delamination at the edges. EVA's cross-linked molecular structure makes it inherently hydrophobic with extremely low moisture absorption. In high-humidity environments such as bathrooms, swimming pools, and canopies, the lifespan of EVA interlayer film for laminated glass far exceeds that of PVB.

3. Processing Adaptability

EVA does not require an autoclave; it can be processed using only a vacuum lamination furnace. Due to its good fluidity, it can perfectly encapsulate embedded materials such as wires, metal mesh, and LED beads. Although its absolute shear modulus is not as high as SGP, EVA film for glass lamination provides a highly cost-effective solution for non-load-bearing semi-structural components (such as interior partitions and non-load-bearing railings).

SGP Interlayer: The Preferred Solution for High-Strength Structural Glass

If EVA is a versatile material, then SGP interlayer is the "heavy weapon" in the structural field. DuPont (now Kuraray) developed this material specifically to address the weaknesses of PVB in structural applications.

1. Overwhelming Advantages in Stiffness and Strength

The data doesn't lie. The tear strength of SGP interlayer for laminated glass is 5 times that of PVB, and its shear modulus (a key indicator of stiffness) is 100 times that of PVB. This means that under the same wind load, laminated glass using SGP deforms minimally, and the two glass panes can work together to bear the load like a single thick pane of glass (coupling effect).

2. Post-Breakage Performance

This is where SGP truly shines.

PVB: After the glass breaks, PVB is too soft, and the glass will sag like a wet blanket and fall out of the frame.

SGP: Even if both layers of glass are completely shattered, the SGP interlayer can still maintain sufficient rigidity to support the fragments in place and even withstand a certain amount of adult weight.

3. Standard for Extreme Scenarios

In hurricane-resistant windows, blast-resistant glass, bulletproof glass, and extra-large curtain wall designs, SGP is almost the only choice. It is the industry's highest standard for structural laminated glass.

PVB Interlayer: Limitations of Traditional Solutions in Structural Applications

Although we emphasize the differences between laminated glass PVB and SGP, this does not mean that PVB is completely useless. It is currently the most widely used interlayer in the world.

Advantages: Low cost, mature supply chain, and acceptable sound insulation performance.

Structural Limitations: As mentioned earlier, PVB is inherently "soft." At high temperatures (above approximately 40°C), the shear modulus of PVB drops sharply, almost losing its ability to transmit shear forces. In addition, it is very sensitive to open edges, and long-term exposure to the outdoors can easily lead to edge defects. Therefore, PVB is more suitable for low-risk applications with four-sided frame support and where the glass is not subjected to constant loads over extended periods.

Laminated Glass EVA vs. PVB vs. SGP: Key Performance Comparison Analysis

To help you understand the differences more intuitively, we have compiled a table comparing the core performance characteristics.

Table 1: Technical Comparison of Structural Interlayers

|

Feature |

Standard PVB |

Clear EVA Interlayer |

SGP Interlayer (Ionoplast) |

|

Shear Modulus (Stiffness) |

Low (< 1 MPa @ 50°C) |

Medium |

Very High (> 50 MPa) |

|

Tensile Strength |

~ 20 MPa |

~ 20-25 MPa (23℃, per EN standard) |

> 34 MPa |

|

Water Absorption |

High (Prone to delamination) |

Very Low (Resistant) |

Low (Resistant) |

|

Post-Breakage Strength |

Poor (Collapse) |

Medium (Holds together) |

Excellent (Structural support) |

|

UV Resistance |

Good |

Excellent (with UV blockers) |

Excellent (Low Yellowing Index) |

|

Processing |

Autoclave |

Vacuum Laminator |

Autoclave |

As can be seen from the table, SGP interlayer is far superior to EVA and PVB in terms of indicators related to 'mechanical performance while Clear EVA interlayer demonstrates unique competitiveness in indicators related to "water" and "processing."

Interlayer Applications: The Optimal Choice for Different Structural Scenarios

There is no best material, only the most suitable material. Based on different interlayer applications, our recommended strategy is as follows:

Table 2: Recommended Interlayers by Application

|

Application Scenario |

Recommended Interlayer |

Why? |

|

Structural Facades & Skylights |

SGP Interlayer |

High wind load resistance; glass stays in place if broken. |

|

Frameless Glass Railings (Outdoor) |

SGP Interlayer |

High stiffness keeps glass upright; withstands weather. |

|

Bathroom / Shower Enclosures |

Clear EVA Interlayer |

Excellent moisture resistance; no edge cleaning required. |

|

Decorative / Smart Glass (PDLC) |

Clear EVA Interlayer |

Low temp processing protects inserts; high clarity. |

|

Standard Windows (Framed) |

PVB Interlayer |

Cost-effective; sufficient safety for framed glass. |

|

Glass Floors / Stairs |

SGP Interlayer |

Critical safety; must support weight after breakage. |

From an Engineering Perspective: How to Choose the Right Structural Interlayer

In actual engineering projects, choosing interlayer technology for laminated glass requires comprehensive consideration of three dimensions:

Load and Safety Level: If glass breakage and detachment would cause casualties (such as in skylights), or if the glass itself is a guardrail (frameless railing), SGP must be chosen. For ordinary interior partitions, Clear EVA interlayer film or PVB for laminated glass is sufficient.

Environmental Resistance: Is the project located by the sea? Is the humidity high? If so, please avoid PVB. Choose SGP or high-quality Clear EVA interlayer to prevent edge delamination.

Processing and Cost: The raw material cost of SGP is usually 2-3 times that of PVB, and the comprehensive cost (including processing) is about 1.5-2 times higher, and it requires an expensive autoclave. If the budget is limited and it's not an extreme structural application, high-performance EVA for semi-structural applications is an excellent compromise. Contact E&N, a professional and experienced supplier of interlayer for laminated glass.

FAQ

Q1: What is structural laminated glass?

Structural laminated glass refers to safety glass that uses a high-strength interlayer (such as SGP or EVA for semi-structural applications) to enable the glass to withstand significant structural loads (such as wind pressure, snow load, and self-weight).

Q2: What are the core differences between EVA, SGP, and PVB interlayers?

In short: PVB is flexible (suitable for automotive/general construction), EVA is weather-resistant and aesthetically pleasing (suitable for decoration/humid environments), and SGP is rigid and strong (suitable for structural/hurricane-resistant applications).

Q3: Why is SGP the preferred interlayer for structural glass?

Because the shear modulus of SGP is approximately 100 times that of PVB, SGP provides "residual strength" after glass breakage, supporting the broken glass fragments like a skeleton and preventing collapse, which is crucial for life safety.

Q4: What application scenarios are suitable for using Clear EVA interlayer?

When you need exposed glass edges (such as in shower enclosures), are in high-humidity environments, or need to laminate special materials (such as silk or PDLC dimmable film), Clear EVA interlayer is the best choice.

Q5: What key factors do I need to consider when choosing an interlayer?

Load, environment, and budget. Choose SGP for high loads, EVA for high humidity/decorative applications, and PVB for general-purpose, low-cost applications.

Conclusion: The Clear Positioning of EVA, SGP, and PVB in Structural Glass

Through the in-depth comparison of laminated glass PVB vs. SGP and EVA above, we can draw clear conclusions:

SGP Interlayer is the guardian of structural safety and a must-have for all high-risk, high-load projects.Clear EVA Interlayer is a perfect combination of aesthetics and function. In non-extreme structural applications and high-humidity environments, its excellent weather resistance and ease of processing make it a strong alternative to PVB.PVB remains the basic choice for standard applications, but in today's modern architecture, where transparency and structural safety requirements are increasingly high, its position is being challenged by the other two.

Choosing the right interlayer for your laminated glass project is not only responsible for the building but also for the life safety of every user.