How Structural Interlayers Work: A Deep Dive into SGP, Clear EVA Interlayer, and PDLC Film Technology in 2026

In the world of modern architecture and glass design, glass is no longer merely a "transparent filler," but has evolved into a "transparent skeleton" that bears loads and protects lives.

From the giant glass curtain walls of Apple headquarters to suspended glass walkways, the safety of laminated glass under hurricane force winds or supporting human weight is often determined not by the glass itself, but by the thin interlayer sandwiched between the glass panes.

Today, we will delve into the microscopic world to explore the working principles of structural interlayers, analyzing how SGP, Clear EVA interlayer, and PDLC film work together at the molecular level.

What are structural interlayers?

Simply put, they are the "strong reinforcement" between glass panes. In ordinary laminated glass, the interlayer mainly serves to bond fragments together; however, in structural applications, the interlayer must possess a very high shear modulus to "lock" the two glass panes together as a single unit when subjected to force.

Understanding the "working mechanism" of the interlayer is more important than simply remembering the material name. Because under extreme conditions (such as storms, explosions, or heavy pressure), the molecular structure of the material determines whether it will stretch like a rubber band (leading to glass collapse) or stand firm like a steel plate (ensuring safety).

Interlayer Technology for Laminated Glass: Basic Working Principle Analysis

Within the framework of interlayer technology for laminated glass, the working logic of any high-performance interlayer must include three core steps:

1. Stress Transfer: This is the foundation of structural integrity. When external force is applied to the glass surface, the interlayer must be sufficiently stiff to evenly transfer tensile and compressive stresses between the two layers of glass, creating a "coupling effect."

2. Energy Absorption: When subjected to high-speed impact, the interlayer absorbs impact kinetic energy through the deformation of its molecular chains, preventing penetration.

3. Structural Redundancy: This is the dividing line between structural interlayers and ordinary interlayers. When the glass breaks, the interlayer must rely on its residual stiffness to ensure that the glass fragments do not detach completely.

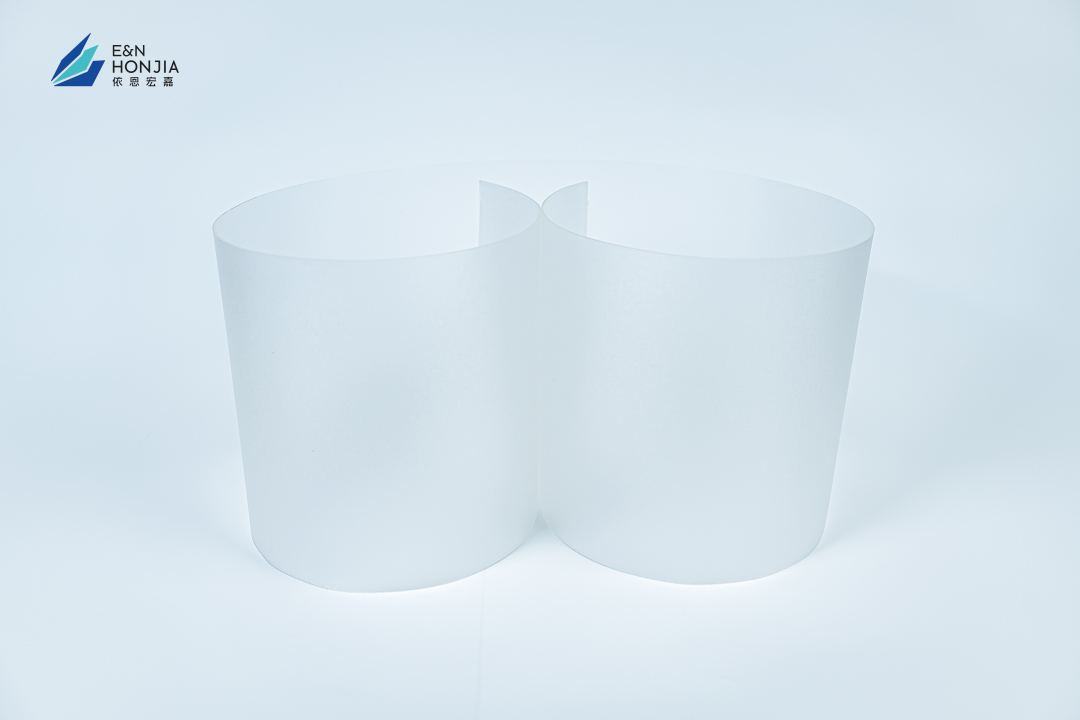

Clear EVA Interlayer: Achieving a Balance Between Structure and Processing

As a star material in today's market, Clear EVA interlayer is redefining the boundaries of decorative and semi-structural glass.

1. Molecular Structure Characteristics: The Magic of Thermosetting

Unlike the thermoplastic nature of PVB (softening when heated), high-performance EVA interlayer film for laminated glass is a thermosetting material. During the lamination heating process, EVA molecules undergo a cross-linking reaction, forming a stable three-dimensional network structure.

2. How it Works

•Stable Bonding: Due to its excellent fluidity before curing, it perfectly penetrates the microscopic irregularities on the glass surface, forming both physical and chemical anchoring.

• Weather Resistance: The cross-linked EVA film for glass lamination has natural hydrophobicity. This means that it will not absorb water and delaminate in environments where the edges are exposed (such as bathrooms and canopies), which is the secret to its much longer service life than PVB.

• Application Scenarios: It is ideal for interior partitions, frameless shower enclosures, and decorative laminated glass requiring high transparency.

SGP Interlayer: The Load-Bearing Mechanism of High-Strength Structural Glass

When it comes to top-level safety and structural load-bearing, SGP interlayer (SentryGlas Plus) is an irreplaceable industry benchmark. It was specifically created to solve the problem of traditional interlayers being "too soft."

1. High Shear Modulus and Stiffness

The shear modulus of SGP interlayer for laminated glass is 100 times that of traditional PVB, and its tear strength is 5 times greater. Mechanically, SGP acts as a "rigid coupling" between the glass panels.

2. Stress Distribution and Structural Synergy

Under stress, glass using SGP interlayer experiences almost no relative slippage. This means that the two pieces of glass can work together like a single thickened piece of glass, greatly increasing the overall load-bearing capacity.

3. Post-Breakage Strength

This is the most amazing aspect of SGP's performance. Even if both panes of glass are completely shattered, SGP, thanks to the ultra-high rigidity of its ionomer polymer, can still keep the glass standing upright in the frame like a "rigid panel," even capable of supporting the weight of an adult, preventing penetrating falls.

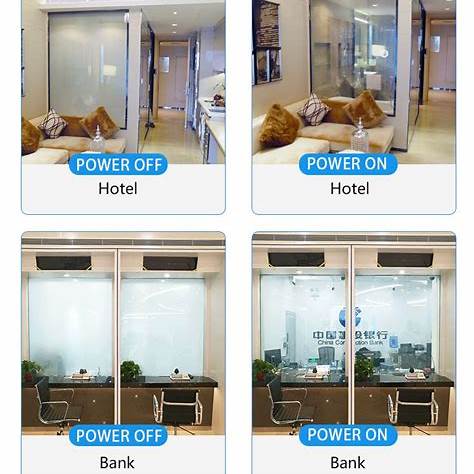

PDLC Film: How Functional Interlayers Work in Laminated Glass

In modern smart buildings, PDLC film (polymer-dispersed liquid crystal film) gives glass "intelligence." But it requires not only electricity but also proper protection.

1. Electrically Controlled Dimming Working Principle

PDLC film for laminated glass is filled with liquid crystal microdroplets.

• Power-off state: Liquid crystal molecules are randomly arranged, light is scattered, and the glass appears frosted (privacy mode).

• Power-on state: Liquid crystal molecules are neatly arranged under the action of an electric field, light passes through, and the glass becomes transparent.

2. Synergistic Approach: Why Must It Be EVA?

PDLC film itself is very delicate and lacks structural bonding strength. PDLC film must be encapsulated between two glass panes with a single layer of Clear EVA interlayer.

• Limitations of PVB: PVB lamination requires high temperature and high pressure (autoclave), and has a large shrinkage rate, which can damage the internal circuitry of the PDLC.

• The Protection of EVA: EVA can flow and cure in a vacuum furnace at a lower temperature (80-110°C). It gently wraps the PDLC and its conductive layer without damaging its delicate electronic structure.

PVB Interlayer: The Working Mechanism and Limitations of Traditional Interlayers

As the oldest PVB interlayer, its core function is "toughness" rather than "rigidity."

• Bonding Principle: It bonds with the hydroxyl groups on the glass surface through hydrogen bonds.

• Working Mechanism: PVB acts like a spring, excelling at absorbing impact energy and sound wave vibrations.

• Performance Limitations: PVB is extremely sensitive to temperature. In environments exceeding 30°C, its rigidity drops dramatically. Furthermore, in high-humidity environments, PVB easily absorbs water, leading to edge delamination; therefore, it is not suitable for use in frameless railings or large-panel structural curtain walls.

Comparison of Working Mechanisms of Different Structural Interlayers

It may be difficult to understand solely through text, so we provide a visual comparison in the following English table to help you understand the differences in interlayer technology for laminated glass:

Table 1: Working Mechanism & Performance Comparison

|

Feature |

SGP Interlayer (Ionoplast) |

Clear EVA Interlayer (Thermoset) |

PVB Interlayer (Thermoplastic) |

|

Primary Mechanism |

High Stiffness & Structural Coupling |

Cross-linking & Chemical Bonding |

Flexibility & Impact Absorption |

|

Shear Modulus |

Very High (> 100x PVB) |

Medium |

Low (Sensitive to Heat) |

|

Post-Breakage |

Stands Rigid (Structural) |

Holds Fragments (Semi-rigid) |

Slumps/Folds (Non-structural) |

|

Moisture Resistance |

Excellent (No Edge Seal Needed) |

Excellent (Hydrophobic) |

Poor (Needs Edge Seal) |

|

PDLC Compatibility |

Low (Process too harsh) |

High (Best Partner) |

Low (Shrinkage issues) |

Interlayer Applications: How Working Mechanism Determines Practical Applications

Once you understand the working principles, the selection of interlayer applications becomes clear:

1. Structural Curtain Walls and Facades: Due to long-term exposure to wind pressure and self-weight, SGP interlayer must be selected to utilize its high modulus to reduce glass deflection.

2. Frameless Glass Railings and Floors: For absolute safety after breakage (to prevent people from falling), SGP is the only option that meets stringent building codes.

3. Interior Partitions and Decorative Laminates: For aesthetics and moisture resistance, high-performance Clear EVA interlayer is the best solution.

4. Smart Glass Systems: Clear EVA must be used with PDLC film to ensure the long-term stable operation of electronic components.

Understanding from an Engineering Perspective: How to Select Structural Interlayers Based on Working Principles

In the engineering selection of interlayer technology for laminated glass, please follow these three logics:

1. Consider the Load: Is there continuous heavy pressure or extreme wind load? If so, SGP interlayer is the first choice. Do not attempt to replace the structural function of SGP with thickened PVB.

2. Consider the Environment: Is it in a humid environment, exposed to high temperatures, or installed outdoors without a frame? If so, resolutely avoid PVB and choose EVA or SGP to prevent aging and delamination.

3. Consider the Process: Is wire mesh, fabric, or dimming function required?

The low processing temperature and vacuum compatibility of EVA film for glass lamination are key advantages for customized glass.

Understanding "how" the interlayer works is far more important than simply comparing prices. A cheap interlayer may lead to delamination of the entire curtain wall after three years, and the replacement cost will be dozens of times the initial investment.

Table 2: Engineering Selection Matrix

|

Scenario |

Recommended Interlayer |

Engineering Reason |

|

Hurricane Zone Facade |

SGP Interlayer |

High stiffness prevents glass from pulling out of frames. |

|

Smart Privacy Bathroom |

Clear EVA + PDLC |

EVA protects PDLC from moisture and heat damage. |

|

Cantilevered Glass Canopy |

SGP Interlayer |

Maintains shape and load-bearing capacity after breakage. |

|

Interior Decorative Wall |

Clear EVA Interlayer |

High clarity and strong adhesion to inserts (fabric/mesh). |

Conclusion: Understanding Structural Interlayers is Key to Successful Laminated Glass

Ultimately, there is no one-size-fits-all interlayer, only the interlayer that is best suited to a specific working principle.

• The core of SGP interlayer's function is "rigidity," making it the guardian of structural safety.

• The core principle of clear EVA interlayer is "stability," serving as the foundation for decorative and smart glass.

• The core principle of PDLC film is "transformation," providing dynamic privacy to spaces.

In the world of laminated glass, choosing E&N as your partner means you've chosen technical experts who understand the "temperament" of materials. Whatever challenges your laminated glass project faces, we can match you with the most suitable interlayer solution.