How Interlayer Technology Defines Laminated Glass Performance and Applications

When we gaze at the glass curtain wall of a modern skyscraper or stand on a suspended glass walkway, we often only see the crystal-clear glass itself. However, what actually determines whether this glass is a safe protective shield or a potential hazard is not the glass sheet itself, but the invisible "muscle" hidden between the two layers of glass—the interlayer.

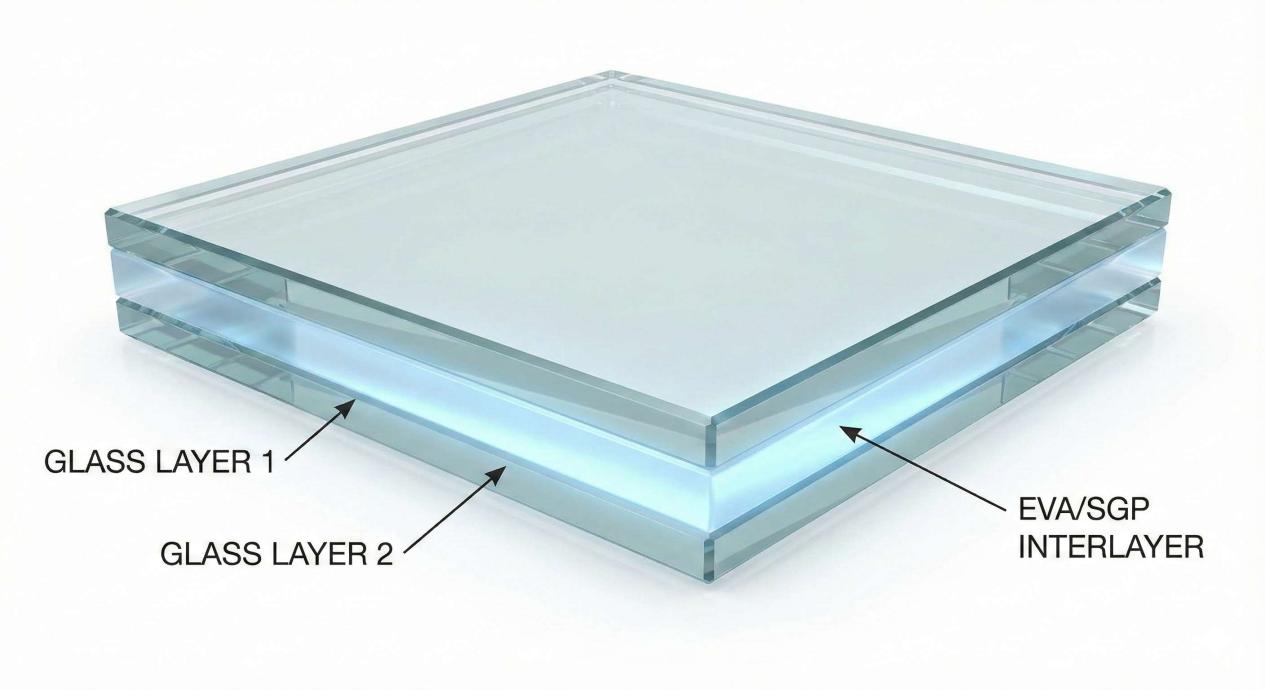

Laminated glass is not simply two pieces of glass sandwiched together with a layer of adhesive. It is a culmination of materials science. As architectural design demands for transparency, safety, and functionality increase, interlayer technology for laminated glass has become a core driving force in defining glass performance.

From the toughness to withstand hurricane-force winds, to the smart technology that allows for instant privacy switching, to UV protection and weather resistance against harsh environmental conditions, all these characteristics stem from innovations in interlayer technology. This article will delve into different types of interlayers such as EVA, SGP, and PDLC, revealing how they are reshaping the application boundaries of glass.

Interlayer Technology: The Key to Laminated Glass Performance

Interlayer technology for laminated glass refers to the technique of permanently bonding glass using polymer materials under high temperature and pressure (or vacuum) conditions. This interlayer forms a chemical bond with the glass surface at the microscopic level, and provides shear modulus, ductility, and optical properties at the macroscopic level.

Different chemical structures of the interlayer determine the vastly different fates of laminated glass:

Guardian of Transparency: High-end EVA interlayer for laminated glass perfectly matches the refractive index of the glass, eliminating "haze" and allowing thick laminated glass to remain transparent.

The Last Line of Defense for Safety: When glass is impacted and shattered, the SGP interlayer, with its high-strength ionic bonds, acts like a "skeleton" to support the broken glass, preventing collapse or penetration.

The Magician of Light: PDLC film for laminated glass utilizes the physical properties of liquid crystals to allow the glass to switch from opaque to transparent in milliseconds.

Understanding these technical principles is a prerequisite for architects and processors to make the correct interlayer selection.

Application Scenarios of Laminated Glass Interlayers

Based on E&N's extensive engineering experience, we have broadly categorized interlayer applications into the following core areas, each with vastly different requirements for the interlayer. Architectural Glass

This is the most widespread application area for laminated glass. Whether it's the curtain walls of skyscrapers, the skylights of shopping malls, or the glass railings of balconies, safety is the primary concern. Here, the interlayer film must pass rigorous impact and weather resistance tests.

Decorative Glass

In interior design, glass needs to be not only transparent but also aesthetically pleasing. In applications such as bathroom partitions, hotel lobby screens, and furniture glass, EVA laminated glass demonstrates excellent compatibility – it can incorporate silk, metal mesh, rice paper, or even plant specimens without producing bubbles.

Smart Glass

With the rise of smart homes and modern offices, switchable glass has become a new favorite. Using privacy glass film technology, conference room glass can freely switch between transparent and opaque states, preserving natural light while protecting privacy.

Advantages and Characteristics of EVA Interlayer in Laminated Glass

In the past, EVA was often mistakenly considered a low-end material. However, with the advent of thermosetting modification technology, modern EVA interlayer film for laminated glass has become a versatile material.

Excellent Anti-Yellowing and Weather Resistance

Compared to traditional PVB, EVA is hydrophobic with extremely low moisture absorption. This means it is not afraid of water. In outdoor applications with exposed edges (such as canopies and railings), EVA will not experience edge delamination or whitening. At the same time, highly cross-linked EVA has strong UV resistance, making it durable and resistant to yellowing.

The King of Decoration and Customization

Clear EVA has unique fluidity when heated. This fluidity is a boon for processors because it can perfectly encapsulate various complex inserts. If you want to create a unique laminated art glass with embedded materials, EVA is the only choice.

Table 1: Key Performance Metrics of High-Quality EVA

|

Property |

Value / Performance |

Impact on Application |

|

Light Transmission |

> 90% - 92% |

Ensures crystal clear vision, no haze. |

|

Cross-linking Rate |

> 85% - 90% |

Determines durability and water resistance. |

|

Adhesion to Glass |

> 75 N/cm - 95 N/cm |

Prevents delamination over time. |

|

UV Block |

> 98% |

Protects interior furniture |

High-Performance Advantages of SGP Interlayer

If EVA represents "gentleness and beauty," then SGP interlayer (Ionoplast) is synonymous with "strength and rigidity."

5 times the tear strength of PVB and 100 times the stiffness

SGP was originally designed for hurricane-resistant glass. It has an extremely high shear modulus, allowing the two panes of SGP laminated glass to work together like a single thick pane when subjected to force, significantly increasing its load-bearing capacity.

Safety after breakage

This is the core advantage of SGP glass. Ordinary laminated glass sags like a wet blanket after breaking, while SGP glass remains upright and can still bear a certain load. This characteristic is crucial for suspended glass floors, frameless glass railings, and skylights.

Application of PDLC Smart Film in Laminated Glass

PDLC film for laminated glass introduces "electricity" and "light" into the world of glass.

Working Principle

In the power-off state, the liquid crystal droplets are randomly arranged, scattering light, and the glass appears frosted (opaque), blocking visibility. When powered on, the liquid crystal molecules instantly align in an orderly manner, allowing light to pass through, and the glass becomes transparent.

Application Scenarios

Medical Privacy: Observation windows in hospital ICU wards, eliminating the hassle of dust accumulation on curtains.

Business Offices: Boss's office or conference room, one-button transparency switching.

High-End Residences: Bathroom glass, providing both transparency and privacy when needed.

It is worth noting that PDLC film requires encapsulation via a low-temperature lamination process, typically using a'sandwich' structure (glass + EVA + PDLC + glass) or double EVA layers (glass + EVA + PDLC + EVA + glass) for enhanced protection

How to Choose the Right Interlayer Film for Laminated Glass

Having trouble choosing? We've summarized a simple decision matrix for you. The choice of interlayer technology for laminated glass depends entirely on your project needs.

Choose SGP: If you are concerned about structural strength, hurricane resistance, fall protection, or if the glass is frameless.

Choose EVA: If you are concerned about decorative aspects (interlayer fabrics), long-term exposure to moisture at the edges (bathrooms, canopies), or if you are looking for high cost-effectiveness.

Choose PDLC: If you need dynamic privacy control and a sense of technology.

Table 2: Comparison of Interlayer Types by Application

|

Application Scenario |

Recommended Interlayer |

Why? |

|

Frameless Balustrade |

SGP Interlayer |

High stiffness keeps it upright; safe if broken. |

|

Interior Partition / Decor |

EVA Clear |

High transparency; compatible with fabric inserts. |

|

Shower Enclosure |

EVA Film |

Excellent moisture resistance; edges won't delaminate. |

|

Conference Room Privacy |

PDLC + EVA |

Switchable privacy on demand. |

|

Structural Glass Floor |

SGP Glass |

Critical post-breakage strength for human safety. |

FAQ

Q1: What is laminated glass?

A: Laminated glass is a type of safety glass made by bonding two or more layers of glass together with a polymer interlayer under high temperature and pressure.

Q2: How does the interlayer affect the performance of laminated glass?

A: The interlayer technology for laminated glass determines the glass's safety (shatter resistance), structural strength, optical properties (transparency), weather resistance, and functionality (such as sound insulation and heat insulation).

Q3: What are the differences between EVA and SGP interlayers?

A: SGP interlayer is harder and stronger, suitable for load-bearing structures; EVA interlayer film for laminated glass is more flexible, has good decorative compatibility, and offers better moisture resistance than traditional PVB.

Q4: What application scenarios are suitable for PDLC smart film?

A: Switchable glass is widely used in office partitions, hotel bathrooms, medical institutions, and commercial display windows requiring dynamic privacy protection.

Q5: How to choose the right interlayer type?

A: A comprehensive consideration of the usage environment (indoor/outdoor), stress conditions (load-bearing/non-load-bearing), and functional requirements (decoration/privacy) is necessary. It is recommended to consult a professional supplier for technical support.

Conclusion: Choosing the right interlayer to optimize the performance of laminated glass

In the world of glass, the invisible interlayer technology for laminated glass is often more important than the visible glass itself.

Whether you are an architect pursuing ultimate safety, a designer pursuing artistic effects, or a tech enthusiast pursuing intelligent experiences, you can find your solution in EVA, SGP, and PDLC.

- EVA gives glass unlimited decorative possibilities and weather resistance.

- SGP gives glass strength and safety beyond limits.

- PDLC gives glass intelligence and dynamism.

At E&N, we not only provide high-quality EVA clear, SGP glass materials, and privacy glass film, but also leverage our 20 years of industry experience to provide you with comprehensive technical support from material selection to processing.

Don't let the wrong interlayer compromise your project. Contact E&N today to find the perfect match for your laminated glass needs.