What is the Best PDLC Smart Film?

In the wave of intelligent building glass and interior design, a material is transforming our spatial experience with the magic of "switching between reality and illusion with a single click." That material is PDLC Film.

From high-end office building conference rooms to luxury hotel bathrooms, this magical film, capable of instantly transforming from frosted to transparent, is redefining the boundaries between privacy and openness. However, with products on the market varying greatly, what exactly qualifies as the "Best PDLC Film"?

Today, this article will delve into the core technology of PDLC film, providing you with a professional guide to selecting and applying PDLC smart film.

What is PDLC Film?

First, we need to understand what PDLC Film is.

PDLC stands for Polymer Dispersed Liquid Crystal. As its name suggests, it is a high-tech thin-film material in which liquid crystal droplets are dispersed within a polymer matrix.

Its core magic lies in its "electronically controlled bistable state":

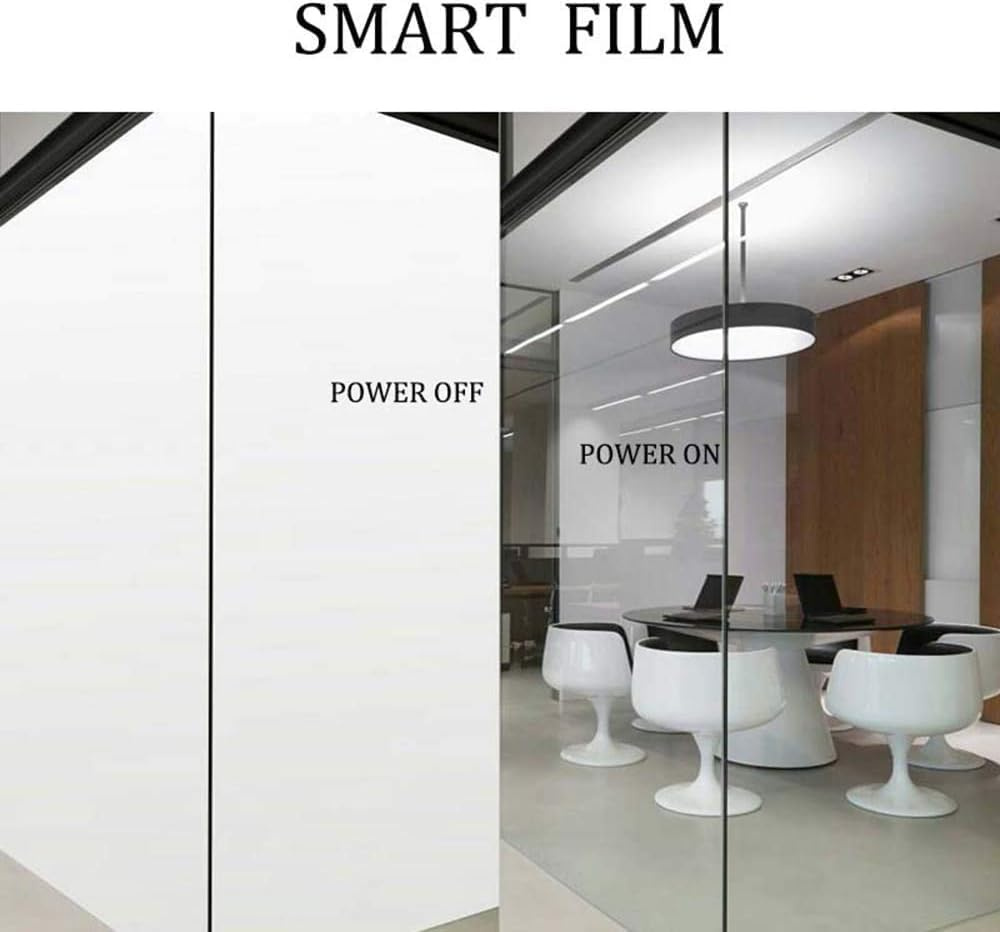

In the off-state (OFF): the liquid crystal molecules are disordered, light is scattered, and the glass becomes frosted (opaque), protecting privacy.

ON (Electrified): Under the influence of an electric field, the liquid crystal molecules align themselves neatly, allowing light to pass through, and the glass instantly becomes transparent.

Because of this switchable characteristic, PDLC film is often called PDLC smart film or privacy glass film. It is the most mature and widely used core material in modern smart glass technology.

PDLC Film Structure and Working Principle

To understand why some PDLCs perform better, it is essential to understand their "sandwich" structure.

A standard PDLC film consists of two flexible transparent conductive films (ITO film) sandwiching a liquid crystal polymer mixture layer in between.

How PDLC Smart Film Works: When alternating current (AC) is applied to the conductive layer, the electric field passes through the intermediate liquid crystal layer.

Without an electric field: The molecules within the liquid crystal droplets are randomly oriented. When light enters, it undergoes strong scattering at the interface between the droplets and the polymer, resulting in a milky white, opaque film.

With an electric field: The liquid crystal molecules align themselves neatly along the direction of the electric field. At this point, the refractive index of the liquid crystal matches that of the polymer, scattering disappears, light passes directly through, and the film becomes transparent.

This physical change enables switchable glass to achieve millisecond-level privacy switching.

Key Performance Indicators of PDLC Film

Many customers ask, "Why is there such a large price difference in PDLC films on the market?" The truly best PDLC film must excel in the following key indicators.

Table 1: Key Performance for High-Quality Self-adhesive PDLC Film

|

Parameter |

Typical Value |

Description |

|

Visible Light Transmission (ON) |

~84% |

Transparency in ON state |

|

Visible Light Transmission (OFF) |

~5% |

Opaque/Frosted in OFF state |

|

Haze (ON) |

~5% |

Low haze ensures clear vision |

|

Haze (OFF) |

~90% |

High haze for full privacy |

|

Viewing Angle |

~120° |

Wide visual clarity |

|

UV Blocking |

ON: >90% / OFF: >98% |

Strong UV protection |

|

Operating Voltage |

AC 60V |

Safe low-voltage operation |

|

Switching Time |

OFF → ON: ~10 ms / ON → OFF: ~50 ms |

Instant privacy control |

|

Power Consumption |

~12 W/m² (ON state) |

Energy efficient |

|

Thickness |

0.3 – 0.4 mm |

Film thickness |

|

Roll Size |

1.2 m / 1.5 m / 1.8 m × 30–50 m |

Custom cutting available |

|

Operating Temperature |

–20 °C ~ +70 °C |

Wide temperature range |

|

Service Life (Indoor) |

>50,000 hours |

Long-term reliable performance |

Key points for selection: The best PDLC film should offer extremely high transparency (low haze) when powered on and excellent shielding when powered off. If a sample you see still appears white (high haze) when viewed from the side after being powered on, it is definitely not a high-quality privacy glass film.

Types and Comparison of PDLC Films

When purchasing, you will encounter two main types of PDLC. Understanding their differences is crucial.

PDLC Film for Laminated Glass (Laminated Non-Adhesive Film)

PDLC Film for lamination glass is a non-adhesive smart film designed for laminated glass processing. By integrating into glass panels through autoclave or vacuum lamination, it delivers instant switchable privacy and light control. When powered on, the liquid crystal molecules align, allowing up to 70% light transmission for a clear and bright view. When powered off, the film scatters light, turning opaque with a haze level above 90%, ensuring complete privacy.

This film combines functionality with safety, making laminated smart glass both durable and intelligent. With low operating voltage (AC 36V), fast switching speed (as quick as 10 ms), and low power consumption (~3 W/m²), it is energy-efficient and reliable. It also blocks over 99% of harmful UV rays in OFF state, protecting interiors and extending the life of furnishings.

Lamination PDLC Film is widely applied in office partitions, meeting rooms, hotels, residential windows, hospitals, and architectural façades. Offering long service life, wide temperature resistance, and customizable roll sizes, it is the ideal choice for manufacturers seeking high-performance smart glass solutions.

Self-adhesive PDLC Film (Self-adhesive Dimming Film)

Self-Adhesive PDLC Film is a practical retrofit solution that instantly transforms ordinary glass into smart switchable glass without the need for lamination. Designed with a thin multi-layer structure for durability, it can be easily applied onto existing glass surfaces, making installation fast, clean, and cost-effective.

When powered on, the film delivers high transparency with parallel light transmittance of around 80%, creating a bright and open view. When powered off, it turns opaque with a transmittance of about 5%, ensuring privacy on demand. Operating at AC 60V with low power consumption of approximately 6 W/m², the film is safe, energy-efficient, and reliable.

With a lifespan exceeding 50,000 hours, Self-Adhesive PDLC Film is ideal for upgrading office partitions, hotel bathrooms, residential windows, retail displays, and advertising panels. Combining modern aesthetics with advanced functionality, it offers a versatile solution for spaces that require flexible privacy and light control.

Table 2: PDLC for Laminated Glass vs. Self-adhesive PDLC

|

Feature |

Laminated PDLC Film |

Self-adhesive PDLC Film |

|

Application Method |

Sandwiched between two glass panes using EVA interlayer. |

Applied directly to existing glass surfaces (Retrofit). |

|

Durability |

Extremely High (Protected by glass). |

High (Requires careful edge sealing). |

|

Main Usage |

New construction, high-end partitions, bathrooms. |

Renovation, office glass walls, shop windows. |

|

Processing |

Requires Lamination Oven / Autoclave. |

Requires Squeegee and clean installation environment. |

Main Application Scenarios of PDLC Film

As a multi-functional switchable glass solution, PDLC applications have long since transcended simple privacy protection.

Office Spaces: Meeting Room Glass Partitions. Transparent when powered on, showcasing an open culture; fogged up when powered off, instantly entering a private discussion mode, also functioning as a projection screen.

High-End Hotels and Residences: Bathroom glass partitions are the most classic application of privacy glass film. It solves the problem of limited bathroom space, ensuring both transparency and absolute privacy while showering.

Medical Institutions: Replacing traditional curtains. PDLC glass is easy to clean, does not breed bacteria, and is ideal for isolation and observation in ICU wards and nurseries.

Commercial Displays: As a smart shop window. Transparently displaying products during the day; at night, when powered off, it transforms into a giant high-definition advertising screen with rear projection.

PDLC Film Customer Pain Points and Solutions

Through communication with numerous customers, we discovered typical pain points caused by using inferior PDLC film.

Pain Point 1: Appears "grayish" or "foggy" when powered on. This is the most common complaint.

Causes: Outdated liquid crystal formulation or uneven polymerization process leads to excessive on-state haze, resulting in poor side-viewing performance.

Solution: Choose a high-transparency formulation product with a nominal haze of <4%.

Pain Point 2: Black spots or edge transparency appear after one year of use.

Causes: Poor sealing allows moisture intrusion, or acidic silicone sealant corrodes the liquid crystal layer.

Solution: Neutral silicone sealant must be used for edge sealing, and a PDLC film manufacturer that has undergone rigorous aging tests must be found.

Pain Point 3: Unstable voltage, or even flickering.

Causes: Inferior power transformer used.

Solution: PDLC smart film must be used with a dedicated regulated power supply to ensure stable driving voltage and extend the liquid crystal life.

How to Choose the Best PDLC Film?

If you are a purchasing manager or designer, please follow these steps to screen for the best PDLC film:

Look at the data and the samples: Request an A4 sample. After powering it on, observe it both close to and away from the text. A good film should remain clear from any angle.

Check the viewing angle: Tilt the powered sample 140 degrees and observe. Inferior films will turn milky white, while high-quality films will remain transparent.

Assess the manufacturer's professionalism: Top PDLC film manufacturers will provide complete technical parameter sheets, aging test reports, and detailed glass processing guidelines.

Confirm the control method: Modern PDLC smart films should support diverse controls: wall switches, remote controls, mobile apps, and even voice control (such as Alexa/Google Home).

Pay attention to width: Reputable manufacturers can provide wider films (such as 1.8 meters or even 2 meters), which means fewer seams on large-size glass, resulting in a more aesthetically pleasing appearance.

PDLC Film Processing Methods: The Formation of Switchable Glass

For glass deep processing companies, correct glass processing technology is the lifeline of quality.

Lamination: This is the core of manufacturing switchable glass.

Correct Method: Use EVA film in a low-temperature

Vacuum oven for lamination, using generally 120℃ - 125℃. EVA's low-temperature flow properties perfectly encapsulate the PDLC film without damaging its internal structure.

Electrode Installation: Use conductive copper foil to make busbars. Contact points must be secure and properly insulated with insulating tape to prevent short circuits.

Lamination Process: For self-adhesive films, environmental cleanliness is paramount. Even tiny dust particles can form inescapable air bubbles under the film.

Future Trends of PDLC Film

Smart glass technology is evolving rapidly, and PDLC is constantly iterating:

Ultra-Clear: Future PDLC will strive for transparency approaching that of ordinary float glass, completely eliminating "haze".

Low Voltage Drive: The drive voltage will be continuously optimized and reduced for greater safety and energy efficiency.

Patterned PDLC: Through laser etching technology, static effects such as louver textures or logo displays can be achieved. For dynamic pattern changes, the film can be divided into multiple independently controlled zones, making PDLC a medium for dynamic displays.

Combined Functions: Combined with insulated glass units (IGU), Low-E coatings, and even transparent photovoltaic glass, it creates energy-efficient and intelligent building facades for the future.

FAQ

Q: What is the expected lifespan of PDLC film?

A: High-quality PDLC smart film can last 10-15 years or more under normal use, with over 10 million on-off cycles.

Q: Can it be used in damp areas such as shower rooms?

A: Yes, but laminated smart glass must be used, and proper waterproofing and sealing around the edges are essential. It is not recommended to use self-adhesive film directly on the inside of shower rooms.

Q: Does PDLC film consume a lot of electricity?

A: It's very energy-efficient. The power consumption per square meter is typically only around 5W, lower than a regular light bulb.

Q: Since it's called Privacy Glass Film, does it provide sound insulation?

A: Yes. Because PDLC laminated glass is a multi-layered composite structure (glass + EVA + PDLC + EVA + glass), its sound insulation performance is significantly better than ordinary single-layer glass, with a sound insulation improvement of more than 10-15dB (total sound insulation reaches 35-40dB), effectively reducing low-to-mid-frequency noise.

Q: Can I install the self-adhesive film myself?

A: Theoretically, yes, but it's quite difficult. Because bubble removal and circuit connection require professional skills, to ensure effectiveness and lifespan, we strongly recommend that it be installed or guided by a trained professional.

Conclusion: The Logic of Choosing the Best PDLC Film

Ultimately, choosing the best PDLC film is about finding the optimal balance between transparency, stability, and privacy protection.

PDLC is more than just a film; it's the key to smart buildings. It transforms static glass into a dynamic space manager. Whether you're a designer seeking the ultimate visual experience or a homeowner prioritizing practicality, choosing a technically sound and high-quality PDLC film manufacturer is crucial for project success.

E&N is a technologically advanced and experienced supplier of PDLC film, committed to providing industry-leading PDLC smart film and switchable glass solutions. We use stringent standards to deliver the purest transparency and the most secure privacy.