The Ultimate Guide to Silicone Vacuum Bags in Glass Lamination

In the production workshop of laminated glass, we often marvel at the grandeur of the autoclave or the precision of the laminating furnace, but easily overlook a seemingly insignificant yet crucial consumable that determines the fate of every piece of glass – the Silicone Vacuum Bag.

If you've ever been troubled by "ghost bubbles" in the middle of the glass, or had to scrap expensive interlayer due to delamination at the edges, then you must re-examine this production step.

Today, we will delve into the details of the silicone vacuum bag, revealing how it becomes the secret weapon for improving yield in the glass lamination process.

Why is the Silicone Vacuum Bag a Key Consumable in Glass Lamination?

In the world of glass lamination, there are only two enemies: air and uneven pressure.

The production of laminated glass is essentially a "sandwich" making process: two pieces of glass are stacked with an interlayer in between, and then permanently bonded through heating and pressure. In this process, even a tiny amount of residual air will expand into bubbles at high temperatures; and slight pressure unevenness will lead to glass waviness or insufficient bonding strength. This is where the silicone vacuum bag comes in.

It's not just a bag; it's the "lungs" and "hands" of the glass lamination process. It's responsible for continuously extracting air before and during heating (the function of the lungs), and using atmospheric pressure differences to tightly compress the glass and film (the function of the hands). Without a high-quality silicone vacuum bag, even the most expensive laminated glass production line cannot consistently produce qualified finished products.

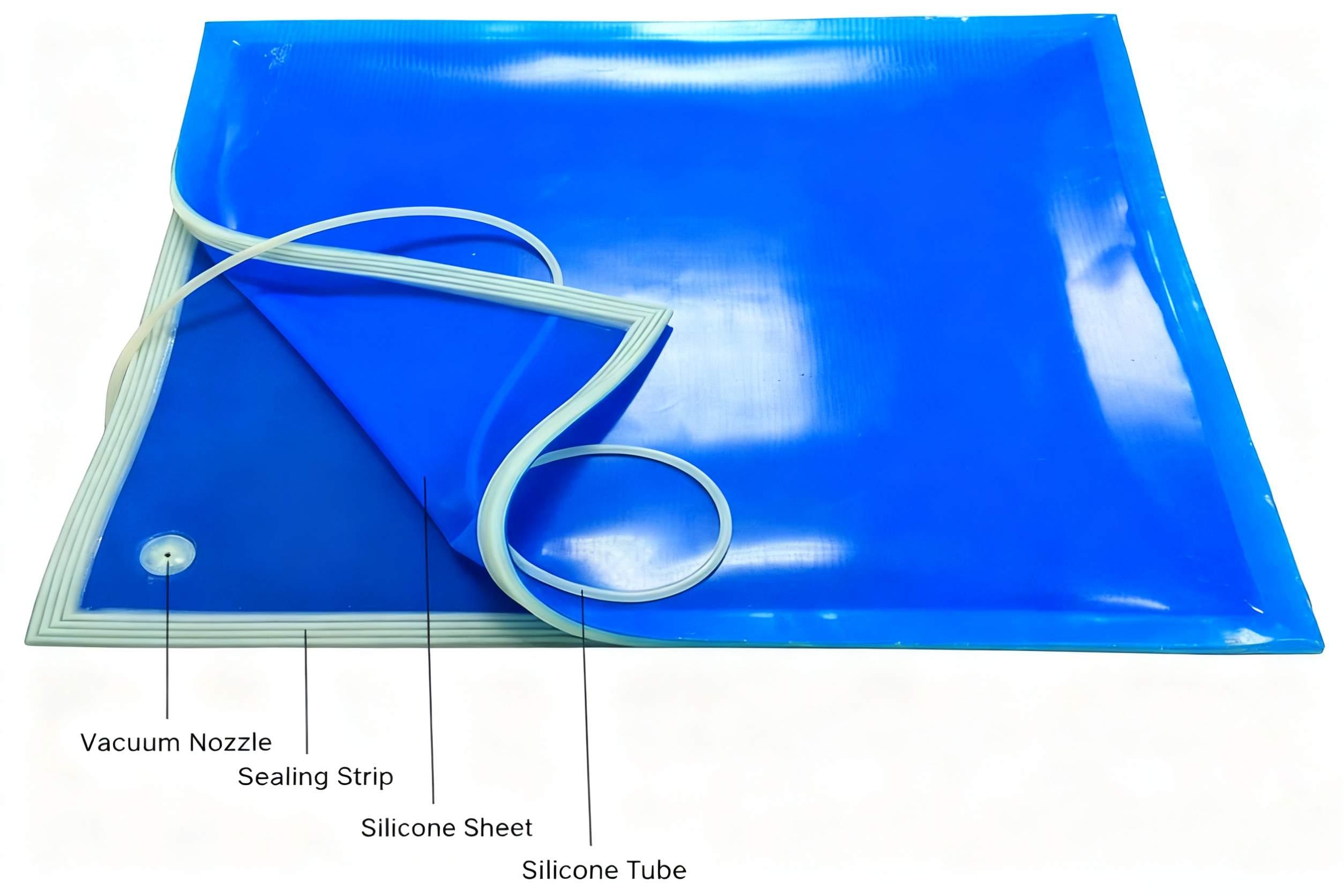

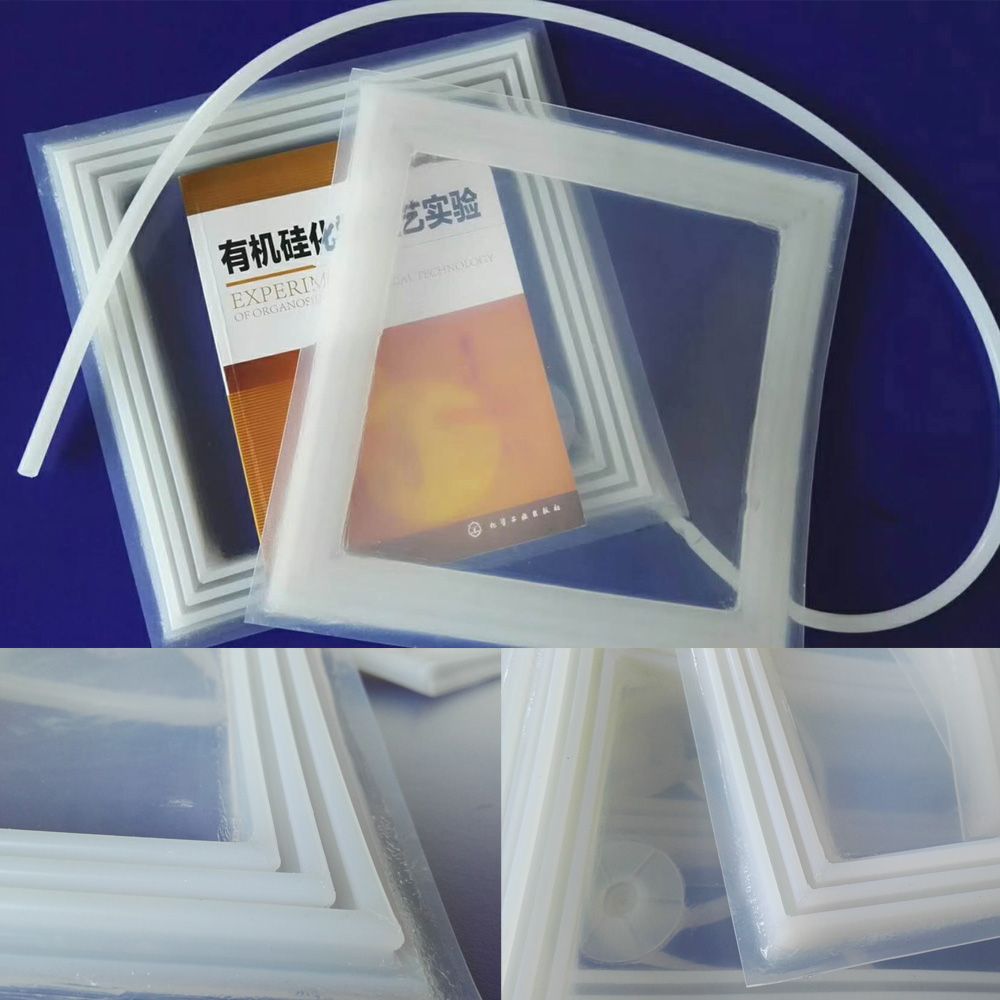

What is a Silicone Vacuum Bag? Basic Structure and Working Principle

Definition and Materials

A silicone vacuum bag (also often called a vacuum silicone bag) is a flexible container made of high tear-resistant, high-temperature resistant silicone rubber. It is specifically designed for the glass lamination process and can maintain stable physical properties under extreme temperature changes and vacuum negative pressure.

Unlike ordinary plastic bags, professional silicone bags have a unique molecular structure (Si-O bonds), which gives them excellent elasticity. Even after hundreds or thousands of high-temperature stretches, it can still return to its original shape, tightly wrapping around irregularly shaped or curved glass. 2. Working Principle: The Art of Negative Pressure

When the vacuum pump is started, the air nozzle connected to the silicone vacuum bag begins to extract air. The air pressure inside the bag drops rapidly, while the outside remains at standard atmospheric pressure.

Utilizing this pressure difference of approximately 1 bar (or 0.1 MPa), the silicone bag adheres tightly to the glass surface like a "second skin." This pressure is omnidirectional and isostatic, meaning that regardless of whether the glass is flat, curved, or wavy, every point on the surface receives uniform pressure. This is the physical basis for successful glass lamination.

The Role of Silicone Vacuum Bags in the Laminated Glass Process

Silicone Vacuum Bags in the Laminated Glass Process

In the specific production process, vacuum bags for glass play three irreplaceable roles:

Complete De-airing: This is the most basic function. Before the interlayer melts and flows, the silicone bag must completely remove the air from the glass interlayer. If this step fails, any subsequent heating will be futile.

Edge Sealing: In the EVA process, the molten adhesive is prone to leakage. High-quality silicone bags provide appropriate edge pressure to prevent excessive adhesive loss and ensure that there is no lack of adhesive at the glass edges.

Positioning: Before entering the lamination furnace, the clamping force provided by the silicone bag fixes the relative position of the glass and the interlayer, preventing slippage during transportation.

Comparison of Silicone Vacuum Bags with Other Vacuum Bags for Glass

Many factories new to the industry try to save costs by using ordinary rubber or even disposable nylon bags. However, in terms of long-term production costs (Total Cost of Ownership), silicone vacuum bags have overwhelming advantages.

For a direct comparison, we have compiled the following table:

Table 1: Silicone Vacuum Bag vs. Common Rubber/Nylon Bags

|

Feature |

Silicone Vacuum Bag |

Common Rubber Bag |

Nylon Bag (Disposable) |

|

Material Base |

High-performance Silicone |

EPDM or Natural Rubber |

Nylon / Plastic Composite |

|

Max Temperature |

Up to 250°C (482°F) |

Approx. 120°C - 140°C |

Approx. 150°C - 180°C |

|

Elongation (Elasticity) |

High (> 700%) |

Low to Medium |

Low (< 100%) |

|

Reusability |

Excellent (Thousands of cycles) |

Poor (Hardens quickly) |

Single-use |

|

Aging Resistance |

Excellent (Anti-ozone/UV) |

Prone to cracking |

N/A |

|

Cost Per Cycle |

Lowest (Long term) |

Medium |

High (Cumulative) |

Conclusion: Although the initial purchase cost of silicone vacuum bags is higher, their high-temperature resistance and anti-aging properties make their cost per use extremely low, making them the only choice for professional glass lamination factories.

Process Requirements of Different Interlayers on Silicone Vacuum Bags

Different interlayers are like "passengers" with different personalities, having different requirements for their "vehicle" (the silicone bag).

1. EVA Interlayer

EVA (Ethylene-vinyl acetate) is currently widely used in autoclave-free processes (Vacuum Oven).

Requirements: EVA requires staged heating (low-temperature degassing, high-temperature curing). The silicone vacuum bag must maintain constant sealing performance over a wide temperature range of 70°C to 135°C and must not become brittle or release volatile substances that contaminate the EVA due to increased temperature.

2. SGP / PVB Interlayer

Although PVB and SGP are typically processed using autoclaves, vacuum bags are also used in pre-nipping or non-autoclave attempts.

Requirements: SGP is harder, which requires the silicone bag to have higher tear strength to prevent sharp glass corners from puncturing the bag during vacuuming.

3. PDLC Smart Film (Smart Dimming Film)

This is the most delicate material.

Requirements: Extremely high surface flatness. If ordinary silicone vacuum bags have coarse textures, the texture will be "printed" onto the PDLC film at high temperatures, leading to visual distortion. Therefore, the production of PDLC laminated glass usually requires custom-made silicone bags with smooth or fine textures.

Typical Application Scenarios of Silicone Vacuum Bags

The flexibility of silicone vacuum bags makes their application scenarios far beyond our imagination:

Irregular and Curved Laminated Glass: Autoclave roller presses can only handle flat glass, while silicone bags can perfectly wrap double-curved, conical, or spherical glass, making them a core technology for irregularly shaped architectural glass.

Artistic Laminated Glass: When fabrics, metal mesh, or plants are sandwiched between glass, uneven thickness is common. The high elongation of silicone bags can compensate for these height differences, preventing the decorative materials from being crushed.

Small-batch Custom Production: For small and medium-sized factories that do not want to invest millions in purchasing an autoclave, a vacuum heating furnace combined with several high-quality vacuum silicone bags can start a glass lamination business.

How to Choose the Right Silicone Vacuum Bag for Glass Lamination

Choosing the wrong bag will not only waste money but also ruin the glass. The following is a professional selection guide:

Table 2: Selection Guide for Silicone Vacuum Bags

|

Parameter |

Recommendation |

Why It Matters |

|

Thickness |

2mm - 3mm (Standard) |

Too thin = easy to puncture; Too thick = poor heat transfer. |

|

Surface Texture |

Smooth vs. Textured |

Textured aids airflow (de-airing); Smooth is for sensitive films like PDLC. |

|

Tear Strength |

≥ 28 N/mm |

Critical for preventing rips from sharp glass edges. |

|

Elongation at Break |

> 600% |

Ensures the bag can stretch over curved glass without snapping. |

|

Connector Type |

Metal vs. Silicone |

Metal is durable; Silicone is flexible. Choose based on your pump interface. |

Expert Advice: When purchasing, be sure to inform the supplier of the type of interlayer you are using and the main glass dimensions. For extra-large glass panels, we recommend custom-made silicone bags with a "multi-channel vacuum system" to ensure that air is efficiently extracted from the central area.

Why choose E&N Silicone Vacuum Bag for Glass Lamination

After understanding the importance of silicone vacuum bags, choosing a reliable supplier becomes the final critical decision.

E&N not only provides general industrial silicone sheets but also has developed high-performance vacuum silicone bags specifically for the glass lamination industry. Our products are designed to address the industry's biggest pain points: short lifespan, easy tearing, and difficulty in sealing large panels.

Here are the core reasons why global glass processing companies choose E&N:

Superior Tear Resistance and Elasticity

The most common cause of rejects in glass lamination is punctures from sharp glass edges. E&N's silicone bags have an ultra-high tear strength of ≥ 28 N/mm and an elongation at break of 500–650%. This means that even when laminating double-curved or complex shaped glass, it can tightly wrap the glass like skin, and still rebound to its original state after thousands of high-temperature cycles, without loosening or becoming brittle.

Large Format Capability

As architectural glass becomes larger, the sealing risks associated with spliced silicone bags also increase. E&N offers seamless silicone bags with a width of up to 3800 mm. This is a rare ultra-wide solution on the market, perfectly suited to the lamination needs of large curtain wall glass, completely eliminating the risk of air leaks from spliced seams.

Optimized Surface Texture

Bubbles are the nightmare of laminated glass. E&N offers a "Textured" option. This special surface texture creates microscopic air channels during vacuuming, ensuring that air is quickly extracted from the center of the glass, greatly reducing laminated glass bubble defects caused by poor air evacuation.

Table 3: E&N Silicone Vacuum Bag Specifications

|

Item |

Typical Value |

Description |

|

Hardness (Shore A) |

55 ± 5 |

Balanced flexibility and sealing strength |

|

Tensile Strength |

≥ 7.0 MPa |

Ensures stable performance during vacuum lamination |

|

Tear Strength |

≥ 28 N/mm |

Excellent tear resistance, durable in repeated use |

|

Elongation at Break |

500–650% |

High elasticity, prevents breakage under stress |

|

Thickness |

2.0–3.0 mm (customizable) |

Standard thickness, other sizes available |

|

Width |

up to 3800 mm |

Suitable for large-format laminated glass |

|

Surface Type |

Smooth / Textured |

Optimized for air evacuation and anti-slippage |

|

Color |

Transparent, Grey, Rust Red (customizable) |

Multiple options for different applications |

|

Service Life |

2000+ cycles |

Excellent heat resistance and durability |

FAQ

In our cooperation with global glass processing plants, we have collected the most common questions about silicone vacuum bags:

Q1: How many times can a high-quality silicone vacuum bag be reused?

A: Under normal operation (no sharp glass punctures, regular maintenance), high-quality silicone vacuum bags can be used for 3000 to 5000 cycles. The main factors affecting lifespan are not the number of uses, but whether they are scratched by glass or severely contaminated with adhesive.

Q2: How to determine if a vacuum bag is aging or needs replacement?

A: Replace the bag immediately if you observe the following signs:

Surface cracking: The silicone starts to harden and develops small cracks (like dry land).

Loss of elasticity: It cannot return to its original shape after stretching, or becomes hard like plastic.

Reduced sealing performance: The vacuum pump works normally, but the vacuum level consistently fails to reach ≤ -0.095 MPa (95% vacuum gauge pressure).

Q3: How to reduce glass lamination defect rates using silicone vacuum bags?

A: 80% of defects come from "false vacuum." Ensure the inside of the silicone bag is clean and free of debris before inserting the glass; use a breather mesh near the air nozzle to prevent the bag from collapsing and blocking the air passage; regularly check that the sealing strip is intact.

Q4: Are all vacuum bags for glass universally compatible with EVA and PVB?

A: Physically, they can be used, but chemically, caution is needed. Some low-quality rubber bags will release sulfides at high temperatures, which can poison and yellow the PVB or SGP interlayer film. Therefore, it is always recommended to use high-purity industrial silicone bags.

Conclusion: Why Silicone Vacuum Bags are the Foundation for Stable Glass Lamination

In the glass lamination industry, which strives for perfection, the silicone vacuum bag is the bridge connecting raw materials and finished products.

It doesn't shine like Low-E glass, nor is it as expensive as SGP film, but the stable vacuum environment and uniform pressure transmission it provides are the last line of defense against bubbles, delamination, and optical distortion.

For any laminated glass factory striving for excellent quality, investing in high-quality vacuum silicone bags is an investment in the yield and reputation of the production line. Don't let a few hundred dollars' worth of low-quality vacuum bags ruin your priceless glass project.

Choose the right tools to make every glass lamination perfect!