How to Choose the Best Interlayers: A Comprehensive Guide to Interlayers for Laminated Glass

In the architectural and decorative glass industry, we often say, "The glass determines the appearance, but the interlayers determine the lifespan." Many project owners or processing plants often focus on the brand of the glass itself, neglecting the importance of the interlayer. However, throughout the entire lifecycle of laminated glass, it is this thin layer of film that performs the core tasks of bonding, shatter resistance, UV protection, and even structural support.

Choosing the wrong interlayer can often have disastrous consequences: edge bubbling due to insufficient weather resistance, delamination caused by insufficient adhesion, or even safety accidents due to insufficient strength in structural applications. For glass processing companies, this not only means high rework costs but also a devastating blow to brand reputation.

This guide will provide an in-depth analysis of mainstream interlayer technologies on the market, helping you find the optimal solution in the maze of interlayer selection.

What are Interlayers? Basic Concepts of Laminated Glass Interlayers

Simply put, interlayers are layers of polymer material located between two or more pieces of glass. Under high temperature and high pressure (or vacuum heating) glass lamination processes, it permanently bonds with the glass, forming a composite structure.

Its core function is not just to "stick" the glass together. Modern high-performance interlayers possess four key mechanisms:

Safety: After the glass breaks, the fragments adhere to the film, preventing injury from flying shards.

Fall Protection: Maintains a certain residual strength after the glass breaks, preventing penetration or falling.

Functionality: Sound insulation, heat insulation, UV protection, and even smart dimming.

Aesthetics: Provides transparent, colored, or textured effects.

For factories pursuing high-quality processing, mastering EVA film for glass lamination or SGP technology is key to improving product yield.

Overview of Mainstream Interlayer Types

Currently, the interlayers on the market are mainly divided into four categories, each with its own advantages:

EVA Interlayers (Ethylene Vinyl Acetate): Especially high-transparency clear EVA, is a favorite for decorative glass, interior partitions, and outdoor frameless railings. It is known for its superior bonding strength and moisture resistance.

SGP Interlayers (Ionoplast): Also known as ionic interlayer film. It is the king of structural glass. When you hear "hurricane-resistant," "glass staircase," or "load-bearing structure," SGP interlayers are the only choice.

PVB Interlayers (Polyvinyl Butyral): The most traditional choice, widely used in automotive windshields and ordinary architectural glass, but its performance in humid environments is not as good as EVA and SGP.

PDLC Interlayers: Polymer Dispersed Liquid Crystal film. PDLC for laminated glass enables the glass to intelligently switch between "transparent when powered on and opaque when powered off," making it a core material for privacy partitions.

Clear EVA Interlayers: The choice for decorative and high-transparency applications

In the past, EVA was often mistakenly considered a low-end material, but modern modified clear EVA technology has completely changed this situation.

Core Performance

High-quality clear EVA has extremely high transparency and extremely low haze. Unlike PVB, EVA is a non-hygroscopic material. This means that its edges will not fog up or delaminate even after prolonged exposure to humid air or water vapor (such as in bathrooms or seaside buildings).

Processing Friendliness

For processing plants with vacuum laminating furnaces, EVA film for glass lamination is extremely user-friendly. It has good fluidity, can perfectly fill the gaps of decorative materials such as wire mesh, fabric, and metal mesh, and can be formed without an autoclave, greatly reducing equipment requirements.

Typical Applications

- High-end interior decorative glass (with wire mesh or fabric).

- Outdoor patio railings (exposed edges).

- Bathroom shower glass.

SGP Interlayers: The first choice for structural glass and high safety levels

If EVA is the master of decoration, then SGP interlayers are the structural giant.

SGP (SentryGlas Plus), originally developed by DuPont, is an ionic polymer. Its tear strength is 5 times that of ordinary PVB, and its hardness is 100 times that of PVB.

Irreplaceable Safety

The most amazing thing about SGP glass is its "post-breakage performance." When both sides of laminated glass are broken, PVB laminated glass will sag and droop like a wet blanket, while SGP laminated glass, due to its high modulus, can still remain upright and bear a certain load. This is the difference between life and death for skylights, glass walkways, and large curtain walls.

Why can't ordinary EVA or PVB replace SGP?

In structural calculations involving personal safety, many international standards (such as ASTM, EN) only recognize the shear modulus contribution of SGP interlayers, thus allowing the use of thinner glass to achieve the same strength and realize lightweight design.

PDLC Interlayers: Smart and Privacy-Oriented Functional Interlayers

With the growth of smart homes and modern office needs, PDLC for laminated glass is experiencing explosive growth.

This interlayer is actually a sandwich structure: the liquid crystal layer is sandwiched between two conductive films. In the power-off state, the liquid crystal molecules are randomly arranged, scattering light, and the glass appears opaque; when powered on, the molecules are arranged in an orderly manner, and the glass instantly becomes transparent.

In actual processing, PDLC film usually cannot be directly bonded to glass, but requires a "sandwich" lamination with two layers of EVA clear film (glass + EVA + PDLC + EVA + glass). This severely tests the selection of interlayers—a special EVA film with low temperature, high transparency, and low shrinkage must be used, otherwise it is very easy to cause the liquid crystal inside the PDLC to fail or produce bubbles.

Core Advantages of Clear EVA and SGP Interlayers Compared to PVB

To intuitively demonstrate the differences, we analyze why the high-end market is abandoning traditional PVB through the following comparison.

Clear EVA Interlayers vs PVB

Moisture resistance: PVB is extremely susceptible to water absorption, and the edges must be sealed with sealant, otherwise it is prone to whitening; EVA clear is not afraid of moisture and is suitable for exposed edges.

Compatibility: PVB will undergo chemical reactions or poor bonding with many decorative inserts (such as metal, fabric); EVA film for glass lamination is thermosetting and can perfectly encapsulate various inserts.

SGP Interlayers vs. PVB

Load-bearing capacity: SGP glass maintains high hardness even at high temperatures, while PVB softens and loses shear strength as the temperature rises.

Yellowing Index: High-quality SGP interlayers have excellent UV resistance and remain transparent after long-term use, while ordinary PVB tends to yellow over time.

Table 1: Comparison of Key Performance Indicators

|

Feature |

PVB Interlayers |

Clear EVA Interlayers |

SGP Interlayers |

|

Shear Modulus (Stiffness) |

Low |

Medium |

Very High |

|

Moisture Resistance |

Poor (Absorbs water) |

Excellent (Waterproof) |

Good |

|

Adhesion to Glass |

High |

Very High |

Extremely High |

|

Post-Breakage Strength |

Low (Collapses) |

Medium |

High (Stands upright) |

|

UV Resistance (Yellowing) |

Medium |

High |

Excellent |

|

Processing Requirement |

Autoclave |

Vacuum Bag / Oven |

Autoclave (Strict Control) |

How to Choose the Most Suitable Interlayers Based on Application Scenarios

There is no single best film, only the most suitable Interlayers for the specific application. Here are our expert recommendations:

Interior decoration and partitions: EVA clear is the first choice. It provides the best visual transparency and can be combined with various colors and materials.

Bathrooms and humid environments: EVA is recommended, as PVB has a shorter lifespan in such environments.

Smart privacy glass: Choose PDLC for laminated glass with special low-temperature EVA.

Glass stairs, floors, and skylights: SGP glass is recommended for safety reasons.

Curtain walls in coastal hurricane zones: SGP interlayers are the only option that can pass large missile impact tests.

Comparison of Key Performance Indicators of Interlayers

When reviewing supplier technical data sheets (TDS), you need to pay attention to the following core indicators:

Light Transmission: High-quality EVA clear should be above 91%.

Haze: The lower the better, especially for multi-layer laminated glass.

Adhesion Strength: Usually tested by the Pummel Test, SGP interlayers usually achieve the highest rating.

The appropriate interlayer thickness for laminated glass varies depending on the application scenario. Please contact E&N for recommendations on the most suitable interlayer for your needs.

Common Customer Selection Mistakes and Solutions

As a manufacturer with 20 years of experience, we have seen too many tragedies caused by incorrect selection:

Mistake 1: Using ordinary PVB for outdoor frameless railings to save money.

Consequence: Severe edge delamination and whitening after six months.

Solution: Switch to hydrophobic EVA film for glass lamination or SGP.

Mistake 2: Believing that all EVAs are the same.

Consequence: Using low-quality thermoplastic EVA, resulting in glass slippage and adhesive flow at high temperatures in summer.

Solution: Be sure to choose thermoset high-crosslinking EVA clear.

Mistake 3: Applying PVB processing parameters to SGP.

Consequences: SGP glass develops bubbles or cracks after cooling.

Solution: SGP requires stricter cooling rate control. Please consult a professional supplier for technical parameters.

How to Choose a Reliable Interlayers Supplier

Choosing a supplier is not just about buying materials, but about buying "certainty."

Batch stability: Ensure consistent thickness and shrinkage rate for each roll of interlayers, which is crucial for automated production lines.

Technical support: Can the supplier provide specific glass lamination temperature curve recommendations?

Certification system: Has the product passed EN, ANSI or SGCC certification? This is a stepping stone to entering the European and American markets.

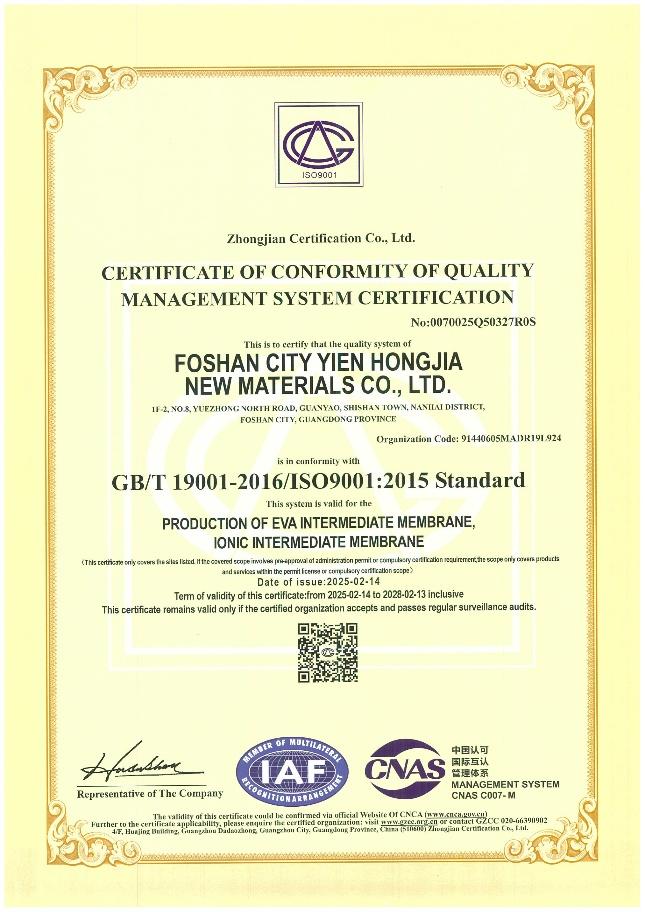

Interlayers Certification - E&N

Full-range capabilities: Excellent suppliers (such as E&N) can usually provide EVA, SGP, and supporting consumables (such as vacuum bags) simultaneously, enabling one-stop procurement.

Development Trends of Interlayers: High Performance + Functionalization

Looking ahead, laminated glass interlayers are evolving in two directions:

Ultimate aesthetics: Whiter, more transparent, and non-yellowing EVA clear formulations for life.

Ultimate functionality: PDLC for laminated glass will combine heat insulation and projection functions; SGP glass will develop towards thinner but stronger materials, contributing to carbon reduction in buildings.

Conclusion: There is no "most expensive" interlayer, only the "most suitable" choice.

In the world of laminated glass, price is not the only criterion. While SGP interlayers are expensive, they offer exceptional value in terms of structural safety; Clear EVA, though more affordable, is irreplaceable in decorative applications.

As a fabricator or designer, a deep understanding of the characteristics of each interlayer is essential to finding the perfect balance between design freedom, safety, and cost.

If you are still confused about project selection, or have encountered challenging problems such as bubbles or delamination during production, the E&N technical team is ready to assist you. We not only provide high-quality interlayers but also offer solutions that give you peace of mind.

Ready to upgrade your laminated glass projects? Contact us today for free samples of our Clear EVA, SGP, or PDLC products.