How to Choose EVA Interlayer for Laminated Glass: A Professional Guide to EVA Interlayers

In the glass processing industry, there's a misconception that "as long as the raw glass is good, you can choose any interlayer."

This is an expensive mistake. As the adhesive in the laminated glass interlayer system, the EVA film not only determines the safety of the finished product but also directly affects the glass's appearance and lifespan.

Have you ever encountered this situation: the laminated glass is crystal clear when it comes out of the factory, but three months after delivery to the construction site, the edges start to whiten, fog up, or even turn yellow in outdoor sunlight? This is usually not a problem with the glass itself, but rather due to an incorrect selection of EVA interlayers.

For architects and laminated glass processors, choosing the wrong interlayer means rework, compensation, and damage to brand reputation. Choosing a high-performance EVA, however, can not only improve yield but also open up more high-end application scenarios. This article, drawing on E&N 20 years of manufacturing experience, will teach you how to choose the most suitable EVA film like an expert.

What Is EVA Interlayer for Laminated Glass?

EVA Interlayer for Laminated Glass

EVA (Ethylene Vinyl Acetate) is not simply "glue." In the laminated glass interlayer family, it is a thermosetting material.

Unlike ordinary thermoplastic materials, EVA undergoes a cross-linking reaction during the lamination heating process. This means that its molecular chains form a three-dimensional network structure. Once cured, it becomes an irreversible, strong layer.

A standard EVA laminated glass structure is usually: glass + EVA film + glass (or with silk, PDLC film, etc. sandwiched in between). It is this seemingly transparent thin film that gives the glass explosion-proof, UV-resistant, sound-insulating properties, and excellent decorative versatility.

Core Performance Indicators of Clear EVA

When you receive an EVA clear sample, you shouldn't just look at whether it's transparent now, but also whether it will remain transparent in the future. The following are four key indicators for evaluating the quality of a clear EVA:

Transparency & Haze

This is the most intuitive indicator. High-quality EVA film for glass lamination, such as E&NEVA's Super Clear series, should have a light transmittance exceeding 90% and extremely low haze, less than 0.3%. If the film itself is cloudy, the resulting laminated glass will look like it's covered in a layer of dust.

Cross-linking and Durability

This is crucial for outdoor applications. High cross-linking (≥85%) means a more stable molecular structure, capable of resisting 99% of UV radiation and high temperature and humidity environments. Low cross-linking EVA is prone to aging and yellowing outdoors.

Adhesion Strength

According to E&N laboratory data, high-quality EVA should have an adhesion strength to glass greater than 75 N/cm. This ensures that when the glass breaks, the fragments remain firmly attached to the film, preventing them from falling off and causing injury.

Flow Rate

This is especially important when processing laminated glass with embedded wires or fabrics. Moderate flowability allows the film to fill the texture of the fabric, preventing the formation of bubbles.

Main Types and Application Positioning of EVA Interlayers

Not all EVA is the same. According to E&N product system, we usually divide EVA interlayers into the following categories to meet different needs:

Extra Clear EVA Interlayer

A high-performance outdoor interlayer material, designed for demanding laminated glass applications in outdoor environments.

Applicable scenarios: Building curtain walls, railing glass, automotive glass, and bulletproof laminated glass.

Features: High clarity, safety, durability, and processing efficiency.

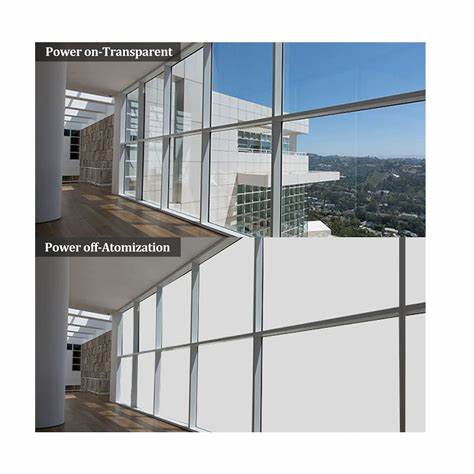

Ultra Clear EVA for Smart Glass

Ultra Clear EVA for Smart Glass

A high-performance interlayer that transforms ordinary glass into smart switchable glass, providing privacy, light control, and safety features.

Applicable scenarios: Smart glass for offices, conference rooms, hotels, and display cases.

Features: Extremely strong adhesion, excellent electrical stability, and ultra-long service life, maintaining reliable performance even after tens of thousands of switching cycles.

Color & Functional EVA (Decorative and Functional Grade)

Includes frosted white (Jade White), milky white, black, and various colored films.

Applicable scenarios: Privacy partitions, background walls, and creative designs.

Table 1: Specifications of Extra Clear EVA Interlayer

|

Item |

Unit |

HJ-HT (Super Clear EVA Film) |

HJ-AT (Super Clear EVA Film – High Fluidity) |

|

Standard Thickness |

mm |

0.38 / 0.76 |

0.38 / 0.76 |

|

Standard Width |

mm |

up to 2600 |

up to 2600 |

|

Length (Roll) |

m |

100 (0.38 mm) / 50 (0.76 mm) |

100 (0.38 mm) / 50 (0.76 mm) |

|

Visible Light Transmittance (VL) |

% |

> 90.4 |

> 90.6 |

|

Haze |

% |

< 0.25 |

< 0.29 |

|

UV Blocking Rate (280–380 nm) |

% |

≥ 99 |

≥ 99 |

|

Crosslinking Rate |

% |

> 85 |

> 85 |

|

Adhesion with Glass |

N/cm |

> 95 |

> 77 |

|

Tensile Strength |

MPa |

> 17 |

> 20 |

|

Elongation at Break |

% |

≥ 750 |

≥ 800 |

|

Water Absorption |

% |

≤ 0.1 |

≤ 0.1 |

|

Weather Resistance |

— |

Pass (100 °C boiling, 85 °C/85% RH) |

Pass (100 °C boiling, 85 °C/85% RH) |

|

UV Aging Test |

ΔYI |

< 1 |

< 1 |

|

Processing Performance |

— |

Standard flow |

High Fluidity – faster flow, better penetration, reduced bubbles |

|

Typical Applications |

— |

Curtain walls, guardrails, automotive glass, bullet-resistant glass |

Curtain walls, guardrails, automotive glass, bullet-resistant glass (especially where high processing efficiency is required) |

How to Choose the Right EVA Interlayer Based on Application Scenarios

Incorrect selection is the primary cause of quality problems in EVA laminated glass. Here is our recommended checklist:

Outdoor vs. Indoor: If the glass is installed outdoors and directly exposed to sunlight, you must choose a high-crosslinking Super Clear EVA. Never use indoor-grade EVA for curtain walls to save costs; otherwise, the glass will yellow after two years, and the replacement cost will be 100 times the cost of the film.

Exposed Edge Applications: For frameless balconies or bathroom glass, the edges are directly exposed to moisture. EVA has natural hydrophobicity (superior to PVB), but you still need to choose EVA interlayers with good hydrolysis resistance.

Wire Mesh/Fabric/Dimming Film: If there are complex inserts in the middle, a film that is too hard can easily cause bubbles. In this case, you should choose an EVA clear film with good fluidity and a moderate processing temperature, or a low-temperature EVA series, to protect the intermediate materials from high-temperature damage.

Key Considerations for EVA Interlayers in Glass Processing (Glass Lamination Factors)

Even with a good film, you still need a good process. The success of EVA film for glass lamination largely depends on the combination of "temperature, time, and vacuum."

Vacuum Lamination Process

Most EVA is processed using a vacuum heating furnace. The key points are:

Cold Vacuuming: The vacuum must be fully applied before heating to remove air.

Segmented Heating: It is recommended to set a low-temperature segment (around 60℃) for insulation, allowing the film to soften and release gas, and then raise the temperature to a high-temperature segment (around 130℃) for crosslinking and curing.

Cooling: The temperature must be lowered to below 60℃ before opening the furnace to prevent the EVA interlayers from shrinking suddenly due to rapid cooling, which can cause edge bubbles.

Customer Pain Points and Solutions for EVA Interlayers

In serving our global customers, we have summarized the most common pain points:

Pain Point 1: Bubbles

Cause: Insufficient vacuum, damp glass surface, or mismatched EVA fluidity.

Solution: Use the special high-temperature resistant tape provided by E&N to seal the edges and ensure a clear vacuum channel; and pre-dry the glass before lamination.

Pain Point 2: High Haze

Cause: Too fast cooling speed or too low lamination temperature, leading to crystallization. Solution: Choose EVA Clear with superior optical performance and extend the curing time to ensure complete solidification.

Problem 3: Overflow

Reason: The EVA melt flow index is too high or the temperature is out of control.

Solution: Use a high cross-linking product, which has a more stable melt viscosity and is less prone to overflow.

Comparison of EVA Interlayer with Other Interlayer Films (EVA vs PVB vs SGP)

Why do we still need EVA when we have PVB and SGP?

Compared to PVB: The biggest weakness of PVB is its water absorption. In humid environments, the edges of PVB are very prone to delamination and whitening. EVA laminated glass, on the other hand, has excellent moisture resistance and is ideal for bathrooms and coastal buildings. In addition, PVB requires autoclave production, which involves significant equipment investment; EVA only requires a vacuum laminating furnace (non-autoclave process), making it more accessible.

Compared to SGP: SGP has the highest strength and is suitable for structural load-bearing applications. However, SGP is expensive and requires extremely high glass flatness. For non-load-bearing decorative glass and partitions, EVA interlayers offer better cost-effectiveness and decorative compatibility (PVB is difficult to laminate with fabrics or wires).

Table 2: EVA vs PVB vs SGP Comparison

|

Property |

EVA Interlayers |

PVB Interlayers |

SGP Interlayers |

|

Moisture Resistance |

Excellent (Waterproof) |

Poor (Hygroscopic) |

Good |

|

Processing Equipment |

Vacuum Furnace |

Autoclave |

Autoclave |

|

Decorative Compatibility |

High (Fabric/Mesh/PDLC) |

Low |

Low |

|

Structural Strength |

Medium |

Low |

Very High |

|

Cost Efficiency |

High |

Medium |

Low (Expensive) |

How to Evaluate the Quality and Performance of EVA Interlayers

Focus on the data. When purchasing EVA film for glass lamination, you can request the following test reports from your supplier:

Peel Strength Test: Verifies adhesive strength.

Boil Test: The sample is placed in boiling water for 2 hours to observe whether blistering or delamination occurs. This is the gold standard for testing crosslinking degree and water resistance.

UV Aging Test: Simulates several years of sunlight exposure to detect the yellowing index (Delta E).

How to Choose a Reliable EVA Interlayer Supplier

The market for EVA brands is mixed. When choosing a supplier, please pay attention to the following points:

Focus: Does the supplier only engage in trading, or do they, like E&N's EVA interlayer, have a clean production workshop and an independent R&D laboratory?

Batch Consistency: Is there a color difference between different batches of clear EVA? A stable formula is a prerequisite for automated production.

Technical Support: When you encounter lamination bubbles, can the supplier immediately provide process adjustment suggestions?

Certification System: Has it passed international certifications such as SGCC, ISO, or TUV?

Development Trends of EVA Laminated Glass

With the increasing aesthetic requirements of architectural design, EVA interlayers are also evolving:

Ultimate Transparency: The light transmittance of the new generation of Super Clear EVA is approaching that of ultra-clear glass itself.

Functional Integration: The combination with PDLC smart dimming film is becoming increasingly close. Dedicated low-temperature EVA film is becoming the standard configuration for smart glass.

Green and Environmentally Friendly: Environmentally friendly EVA with low VOC emissions is favored by high-end markets in Europe and America.

Conclusion: How to Truly Choose the Right EVA Interlayer

Choosing an EVA interlayer is actually a balancing act: finding the best balance between transparency, weather resistance, processing convenience, and cost.

Remember, the cost of EVA interlayers is a small percentage of the entire project, but the risk is significant. Choosing an glass film supplier like E&N, with 20 years of experience and comprehensive technical support, is the best insurance for your project's success.

Still worried about bubbles and yield rates? Contact our technical team immediately to get free samples and the latest lamination process guidelines.